Roll crusher

SOURCE:admin Author:admin DATE:2022-10-27 CLICKS:1674Product Information

Technical parameter

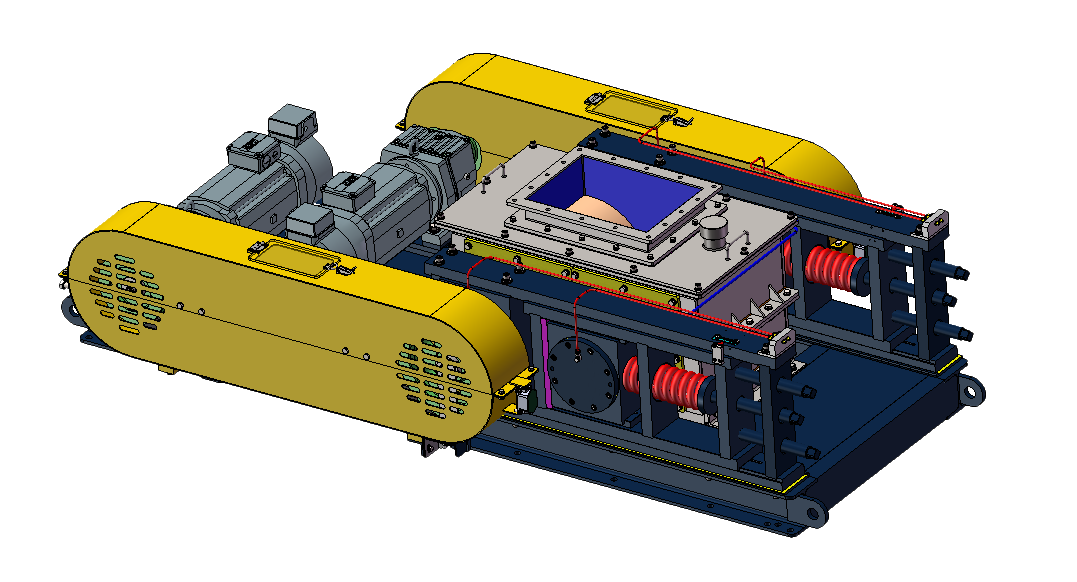

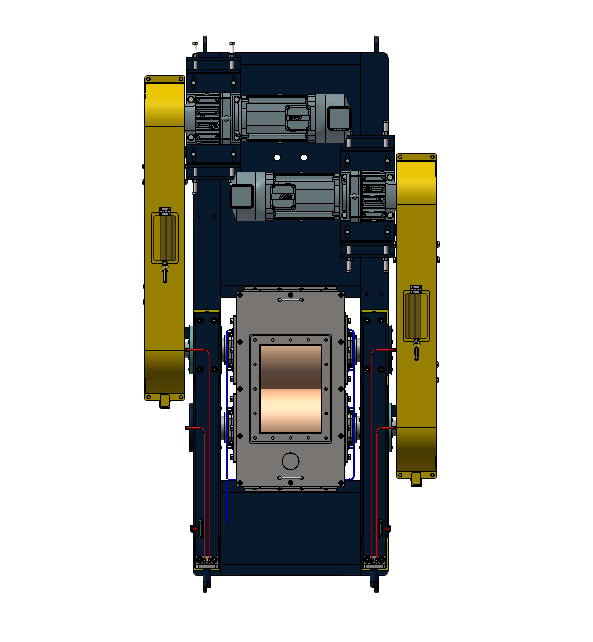

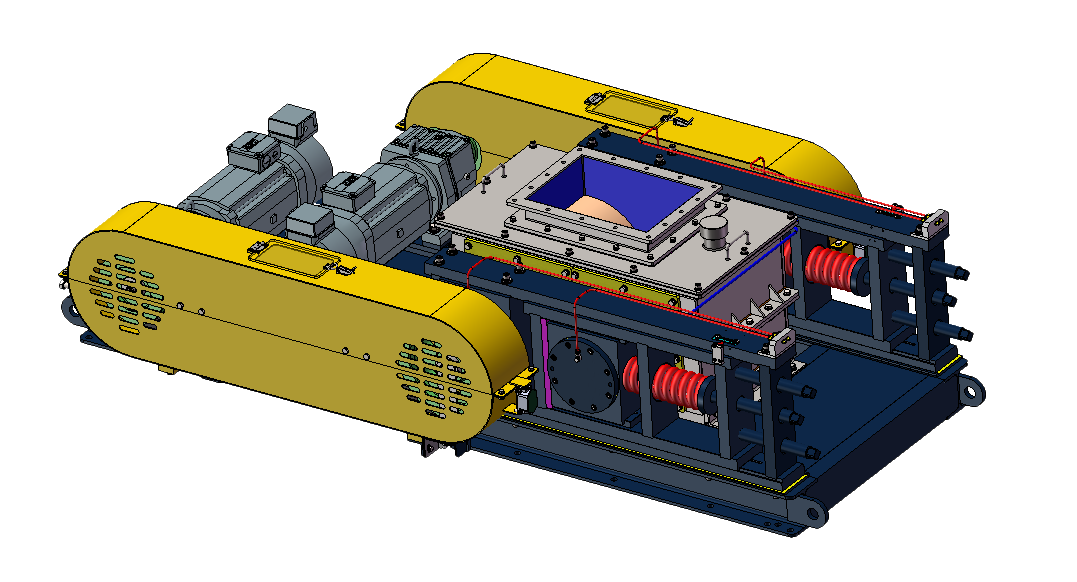

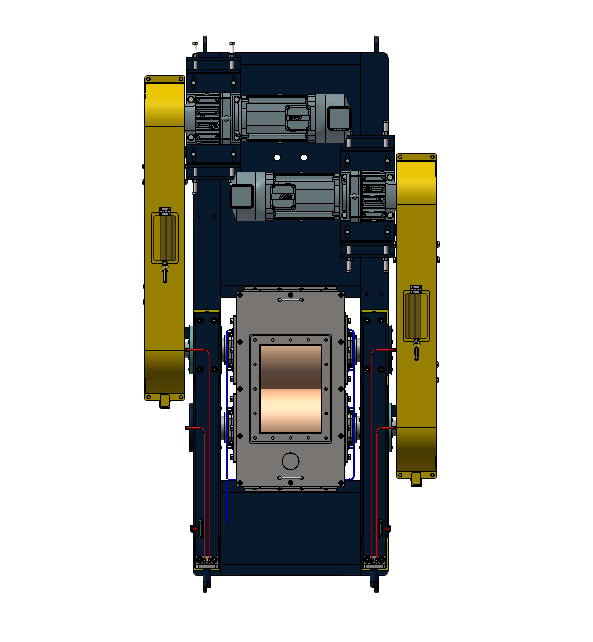

Product display

This model is specially designed by our company for the disintegration of the false particles formed by the agglomeration and agglomeration of the materials generated by chemical method during the production process (such as drying and sintering) in the powder industry. This model is a single-layer roll crusher, and its roll is made of alumina ceramics, which has strong wear resistance, and the crushing process does not pollute materials. The gap between rollers of this machine can be adjusted. The ceramic roller can adopt frequency conversion speed regulation. Adjusting the gap between rollers can enable users to obtain ideal particle products. Adjusting the speed of the ceramic roller can achieve the best crushing effect and productivity.

This machine can be used not only as the primary crushing before mechanical crushing or air flow crushing, but also as the final crushing of some products.

This model has been widely used in the crushing process of various lithium battery cathode materials (such as lithium cobalate, cobalt oxide, lithium iron phosphate, ternary materials, etc.); Other industries such as phosphor, fine chemicals are also widely used.

Technical parameter

| Model | Gp-230x300 | Gp-230x400 | Gp-350x300 |

| Ceramic roll size | φ230x300 | φ230x400 | φ350x300 |

| Power | 2.2kw*2 75r/min |

3kw*2 85r/min |

5.5kw*2 95r/min |

| Raw material particle size | ≤5mm | ≤5mm | ≤5mm |

| Raw material hardness | ≤ Level 7 | ≤ Level 7 | ≤ Level 7 |

| Product particle size | 20~100 mesh | 20~100 mesh | 20~100 mesh |

| Handling capacity | 50-200kg/h | 50-300kg/h | 50-400kg/h |

| Power Supply | 380V/50HZ | 380V/50HZ | 380V/50HZ |

Product display

Related news /about news

Related products /about products